2016

NEW CERTIFICATIONS AND DOUBLE ANIVERSARY

As our clients well know Trafiltubi has been certified according to ISO 9001 since 1997 and PED since 2007, then AD2000-W2. We are now on our way to achieveing the EN 9100 certification: the latter being an important step for us, since we historically produce tubes for aeronautical applications too.

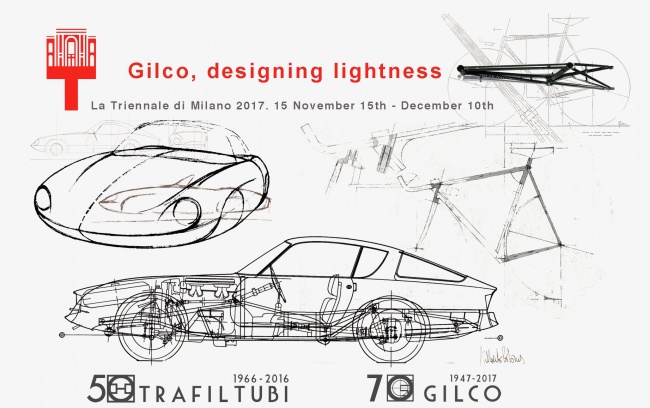

2016 opens a two-year period that - once more - sees a double anniversary, and a very important one to Trafiltubi: i.e. the Fiftieth of Trafiltubi and the Seventieth of the Gilco historical label, two tightly linked realities.

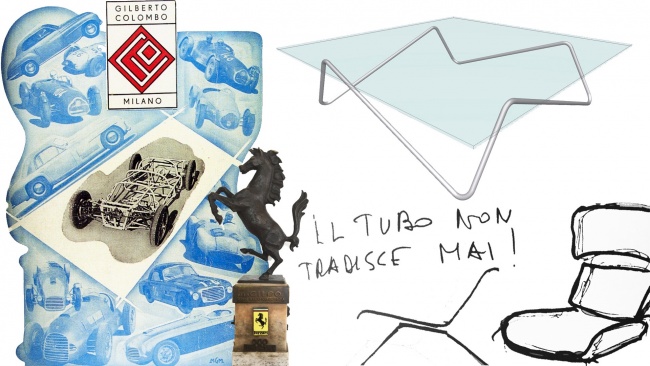

In view of such significant accomplishments, we will start a few new projects as a homage to Gilco and therefore also to the beloved memory of Gilberto Colombo, with the aim to draw value from the huge historical heritage that Trafiltubi still refers to. Among the projects currently in progress, we are proposing a restoring service for Gilco historical frames, based on original drawings. The partnership between Trafiltubi and a workshop that specialises in the assemblage of race cars chassis, including vintage ones, allows the assembling and restoring of such frames, made with Gilco tubes and provided by certification of authenticity.

2015

NEW MATERIALS AND NEW PARTNERSHIPS

In 2015 Trafiltubi included 4130 and T45 in its main catalog, therefore providing for those products a continuous availability in many variations as well as prompt delivery.

For T45, specifically, Trafiltubi has established a distribution agreement for England and Northern Europe: our T45 is distributed in those countries by Aerocommetals, a trustworthy partner who can ensure assistance and guarantee the best possible service.

2014

IMPLEMENTATIONS AND NEW QUALIFICATIONS

2014 has been a very important year for Trafiltubi, because of the intense schedule of improvements (upgrades?) made to the machineries, the Lab and the staff, as well as the range of supplied products.

Indeed, we further enhanced our production capability in shaped profiles, equipping ourselves with new semi-automatic systems for straightening processes and with new precision tools. We also improved the heat treatments and introduced new nuances of steels, in both stainless and high-alloy steels.

We established a partnership with a supplier of welded stainless steel pipes, which allows us to supply those products too, besides the cold-drawn seamless stainless pipes: we buy the raw material and we complete the production cycle with the required heat treatments and final controls.

Lastly, we inaugurated an internal commercial branch, named Trafiltrade, that allows us to handle dimensions and qualities beyond our traditional standards: to this end we first buy tubes of tested quality from selected and qualified suppliers and then our Lab checks and certifies them once more.

NB: We personally work and entirely manufacture all our tubes. The only exception is about the tubes under the name Trafiltrade.